Our Products

Vortex Powered Aeration – Standard (S)

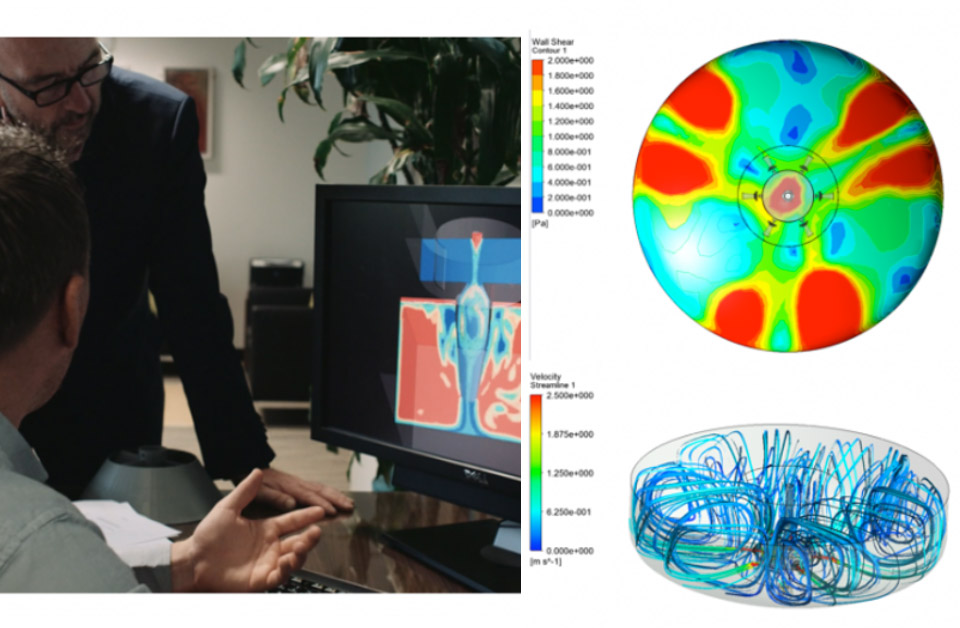

Vortex Powered Aeration (VPA): A new twist in energy efficient upgrades

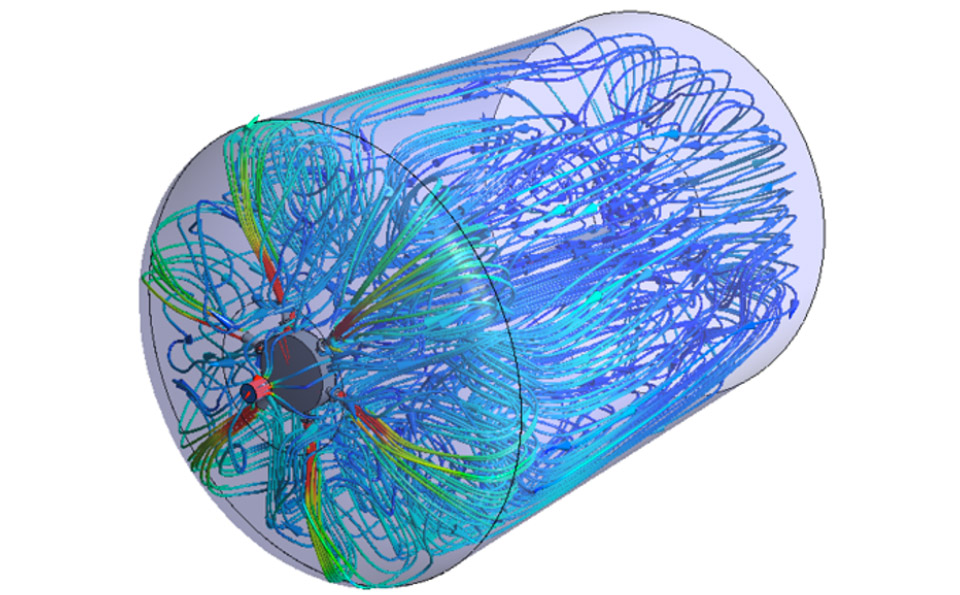

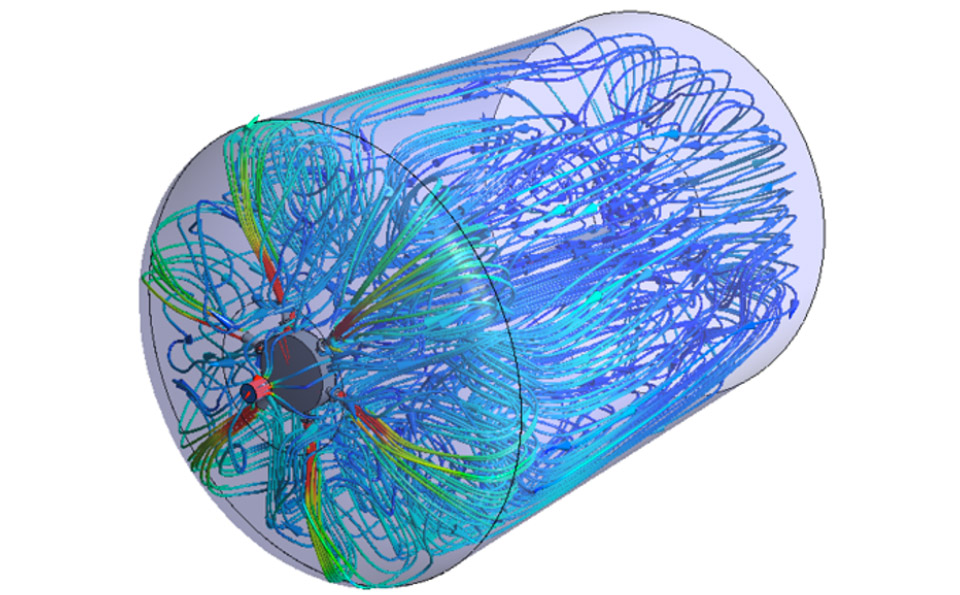

The patented Vortex Power Aerator (VPA), uses a novel cyclonic method of mixing air and water to massively reduce the energy intensity in aeration and mixing processes of wastewater treatment. Instead of relying on costly, high maintenance blowers to pump air, under 4 to 5m of water pressure at the bottom of the tank, the VPA instead lifts water to the surface of the tank where it is mixed with air in a cyclone requiring low pressure and power.

The key benefits of the VPA are:

- LHigh oxygen transfer rate at low power input yielding high aeration efficiency (AE)

- LHigh flows to provide mixing throughout tank whilst simultaneously mixing

- LLow effect of alpha factor with high in process oxygen transfer

- LHigh-quality stainless-steel fabrication with 50-year lifespan

- LHigh-quality, highly-efficient pump with 20-year lifespan

Vortex Powered Aeration – Recovery (R)

The world’s first opportunity to recover energy from the aeration process

Vortex Powered Aeration – Recovery (R)

The world’s first opportunity to recover energy from the aeration process

VorTech’s VPA-R technology provides an opportunity to recovery energy in the aeration process in the form of hydroelectric power. An energy recovery module is installed in the system which captures a portion (up to 30%) of input energy not required in the aeration process.

The energy can be used to off-set the aeration energy costs and significantly reduce the net energy usage at the facility. The energy can also be used directly by other facilities during recovery or can be stored for use when utility energy costs are high.

Mixing

VorTech understand the importance of mixing in your process

- LContact tanks

- LBalance tanks

- LAeration tanks

- LPre and Post-Denitrification tanks

- LSludge holding tanks

Mixing

VorTech understand the importance of mixing in your process

- LContact tanks

- LBalance tanks

- LAeration tanks

- LPre and Post-Denitrification tanks

- LSludge holding tanks

With the VPA technology, there is a feature available which allows the plant to automatically switch between aeration and water only circulation allowing nitrification and denitrification to be carried out in one tank. As well as reducing energy costs, this can reduce the costs of capital outlay for additional equipment and tanks which also reduces the footprint of the facility.

Rental Aeration Systems

Energy efficient emergency or supplemental aeration